All the common lamb feedlot shed terminology, jargon, buzzwords and acronyms explained, so you know what’s what!

Looking to transition from containment feeding your sheep to an intensive finishing system?

Researching lamb feedlot sheds?

Wondering what formed up footings are?

Or if you need to include ridge ventilation?

Using lamb feedlots beyond drought management is a hot topic, and feedlot sheds are becoming popular projects.

Lamb producers with feedlot sheds are proving benefits such as:

- Substantial improvements in growth rates (~150gms a day extra)

- Lower mortality rates during hot and cold months

- Proving significant savings due to minimal feed loss and reduced treatment costs for summer pneumonia

- Taking advantage of substantial water catchment for water troughs

As this infrastructure becomes more common, so does the industry jargon and phrases – from feeder types and shed design features to profitability measures and acronyms.

So, in this article, we provide a back-to-basics A-Z explanation of some of the most common lamb feedlot shed terminology.

Frequently Asked Questions About Lamb Feedlot Sheds – Answered

Quick answers to the top questions about lamb feedlot sheds.

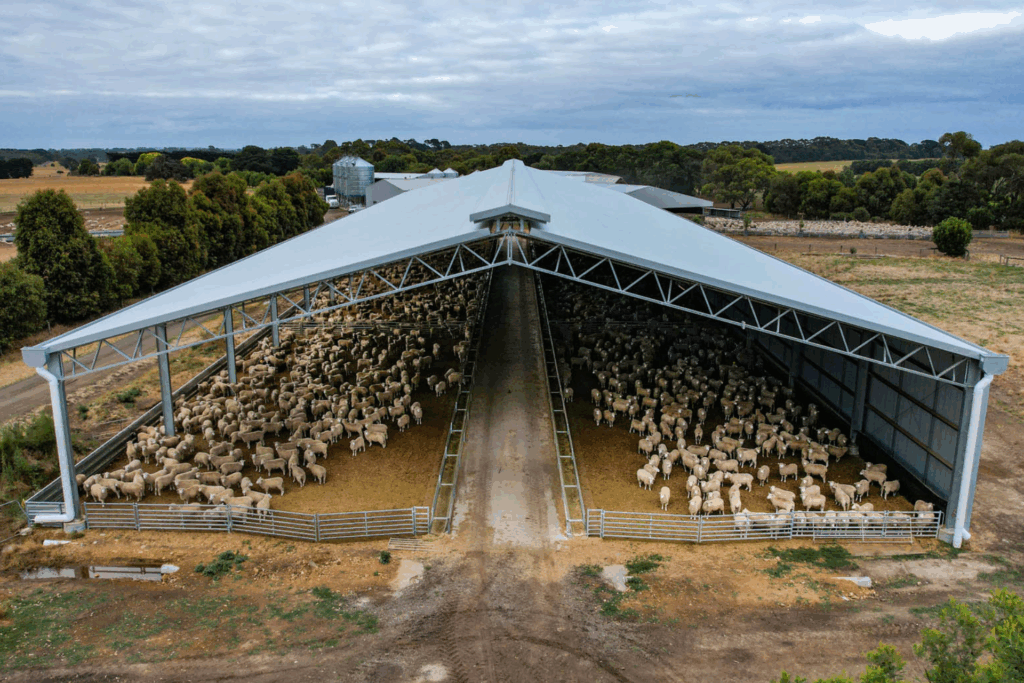

An Action lamb feedlot shed is a structural steel roof designed and built to cover lamb feedlot pens.

Some of the top benefits of lamb feedlot sheds include:

- More consistent carcase weights

- Faster finishing/quicker turnoff

- Improved lamb health and reduced treatment costs

- Reduced feed wastage

- Capturing stormwater run-off

The best lamb feedlot shed design usually starts with a “roof-only” configuration that is then customised to suit your operational requirements (such as feeder type and stocking density) and site conditions (such as the direction of the prevailing weather).

For example, recommended design features include:

- Steep roof pitch (usually between 14 and 18 degrees) that works with an open ridge vent and an Action custom “pop top” ridge cover to provide effective ventilation

- Gable infills, partial walls or walls with sliding doors to achieve practical access and the correct balance of airflow and ventilation

- Stormwater management using the Action custom gutter system (often plumbed to one end)

Other common features include canopies (for cost-effective coverage and convenient column placement) or formed up columns (to lower the risk of injury at sheep level).

The best size for your lamb feedlot shed will depend on factors like:

- How many sheep do you want to house? What is the stocking rate?

- What type of feeder/system are you implementing?

- Will there be a feed lane? Centre or side?

- Will the feedlot be 100% contained or include external pens?

- Are you covering new or existing pens?

- What are your access requirements?

- Do you have plans to expand the feedlot in the future?

However, there are also some industry recommendations and best-practice rules of thumb to consider:

- A stocking rate of around 1m² is common for covered lamb feedlots, including for partial shade set ups.

- Lambs will require 150mm or more per head of bunk space, or if you are using lick feeders, this reduces to around 50mm.

- An eave height of 5 metres is most common for a covered lamb feedlot. This provides adequate clearance for equipment such as tractors and feed wagons, and also helps facilitate effective airflow through the cover.

- Several standard spans work well for lamb feedlot sheds, including 24 metres, 27 metres and 30 metres.

- A cantilevered canopy is a cost-effective way to gain extra coverage/width and can be used over side feed lanes.

- The recommended roof pitch for a lamb feedlot is around 18 degrees. This works most effectively with a 1500mm ridge opening.

Cost-effective and functional bay spacings range from 8 metres to 10 metres. The 10-metre option is common for larger setups for airflow and access (especially if the footings have been formed up).

We take a deep dive into the topic here – What Size Lamb Feedlot Cover Do I Need?

Yes, this is usually possible and can be achieved by:

- Adjusting column lengths to suit any fall or slope over the site

- Varying bay spacings to avoid columns clashing with pens

- Stick building the cover or constructing it to one side and craning into place

The average cost of a lamb feedlot shed is around $750,000, with prices ranging from $250,000 to $1,400,000.

The lamb feedlot shed cost for your project will depend on factors like size, location and design features included.

As a general rule, a lamb feedlot shed costs around $115 – $150/m² including GST, which works out to be around $150 – $160/head.

The cost per head for your project will depend on factors like stocking rate, loafing areas and shed configuration.

Lamb Feedlot Shed Terminology – Explained (A-Z)

First up, acidosis.

A

Acidosis

Also known as grain overload or grain poisoning, acidosis can occur in lamb feedlots when sheep are introduced to grain (or a new type of grain) too quickly.

A

Automated Feeders

Automated feeders, such as those by Feedtech, operate with a silo at one end, where an auger pushes the grain through to the feeders, keeping them topped with grain and controlling the feed (learn about feed control systems here).

Advantages of this system include improved feed intake, reduced wastage and less labour requirements.

B

Backgrounding

Backgrounding is the recommended way to introduce your sheep to a feedlot or intensive finishing system. This helps prevent shy feeders, improves feed intake and reduces health issues.

Backgrounding often involves:

- Introducing sheep to feed bunks and water troughs (or your chosen feed system)

- Establishing mobs and maintaining these in the feedlot to avoid social disruptions

- Allowing sheep to interact in a contained area so that they are exposed to different pathogens and develop a strong immune system

B

Bay Spacing

Bay spacing or bay width refers to the distance between columns.

The bay spacing and the number of bays will determine the length of your feedlot shed.

Common bay spacings for lamb feedlot sheds include 8 metres, 9 metres and 10 metres. These can also be varied through the cover to prevent columns from clashing with pens or gateways, and access points.

B

Bunk Space

Bunk space refers to the amount of room each sheep requires to feed effectively without competition.

Generally speaking, lambs will require 150mm or more per head of bunk space. However, this does depend on:

- The size of the sheep

- The feeding stage, such as induction feeding or feedlotting

- The feeding system, such as bunks or lick feeders, and whether you are feeding from one side or both. For example, if you are using lick feeders, this reduces to around 50mm.

C

Cantilevered Canopy

A cantilevered canopy is an awning that doesn’t require any supporting columns, providing extra coverage and clear space.

For lamb feedlot sheds, canopies are commonly used over a side feed lane to reduce feed wastage, avoid inconvenient column placement and provide clear machinery access.

A canopy is also a cost-effective way to increase coverage. For example, a 24 metre span with a 6 metre canopy will be more cost-effective than a 30 metre span.

C

Computational Fluid Dynamics (CFD)

While not common lamb feedlot shed terminology, Computational Fluid Dynamics is the simulation of how liquids and gases will flow and behave in an environment. For example, heat transfer and ventilation in a feedlot shed.

Our building consultants use research, including Computational Fluid Dynamics studies, to develop functional feedlot shed designs.

This includes:

- Effective airflow for heat, moisture and ammonia reduction and how we can manipulate the roof design to achieve this.

- Functional and cost-effective configurations that satisfy stocking density and bunk space requirements.

- Best-fit orientation depending on feedlot location and climate.

C

Containment Area

Containment feeding (also known as confinement feeding or lot feeding) is a contained area where sheep are kept and fed. This can be achieved with sacrificial paddocks, drought lots or containment pens.

Containment areas protect soil and pasture, make feeding out less labour-intensive and make it easier to meet energy requirements for your flock.

These are the main reasons why containment feeding is implemented as a drought management strategy.

Lamb feedlot pens apply many of the same principles as a containment area, but are typically used for production feeding or an intensive finishing system. A lamb feedlot can also include a loafing area.

C

Cost Of Production (COP)

Cost of Production (COP) is the total cost a company incurs to manufacture or produce a product or provide a service.

This typically includes all direct and indirect expenses and fixed and variable costs.

For primary producers with lamb feedlots, costs to consider include:

- Store lamb costs (if buying lambs in)

- Infrastructure costs

- Feed costs

- Labour costs

- Treatment costs

- Transport costs

Calculating an accurate cost of production – along with growth rate and time on feed – is important for determining the profitability of your lamb feedlot system.

MLA have a Cost of Production calculator, which may be a handy tool for you – you can try it out here.

C

Custom Gutter System

The Action custom gutter system – a standard inclusion on all Action sheds – uses a rolled gutter supported by heavy-duty hot-dip galvanized brackets.

The advantage of this system is that it allows downpipes to be plumbed to one or both ends of the shed, rather than down the face of the column. This prevents damage to the downpipes and directs stormwater away from the feedlot pens.

A lamb feedlot shed provides an excellent opportunity to capture and use stormwater run-off.

Use the calculator below to find out how much stormwater you could capture off your shed roof.

Rainwater Harvest Calculator

If you are wondering about the volume of rainwater you could potentially collect from a shed roof, use the stormwater calculator.

E

Eave Height

Typically, shed height refers to the height of your shed at the eaves.

The most common height for a covered lamb feedlot is an eave height of 5 metres. This provides adequate clearance for equipment such as tractors and feed wagons, and helps facilitate effective airflow through the cover.

F

Feed Bunk

Feed bunks, such as these concrete bunks by Conron, are a popular feeding system for lamb feedlots and are typically used with a centre or side/perimeter feed lane.

It is important to ensure there is adequate separation between your feed bunks and water troughs to minimise contamination.

F

Feed Conversion Efficiency (FCE)

Feed Conversion Efficiency measures how efficiently a sheep converts feed into weight gain.

This is typically calculated as a ratio of the amount of feed (kg) required to produce 1 kg of live weight gain. The lower the ratio, the greater the efficiency.

Factors that influence Feed Conversion Efficiency include:

- Genetics

- Entry weight/condition

- Diet

- Backgrounding

- Feedlot environment

- Number and management of shy feeders

F

Feed Lane

A feed lane is used to access and fill feed bunks with a tractor and feed wagon.

One of the benefits of this system is that bunks can be filled easily without disturbing the lambs, helping to create a low-stress environment.

Feed lanes are typically 5m or 6m wide and can be either centred or to the side, depending on the pen and bunk set-up.

The feed lane location (side versus centre) will determine the shed length and width required. For example, a feedlot shed with a centre lane may require a 30 metre width. However, with a side feed lane, you may be able to achieve this coverage with a 24 metre span and a 6 metre canopy over the feed lane.

F

Formed Up Footings

Formed up footings – like the project examples pictured below – are footings that have been formed up with poly pipe, usually by 300mm.

This provides an additional layer of corrosion protection, maximising the longevity of the galvanized footing cages.

Formed footings also provide separation between the column and the bedding and minimise the risk of injury to the lambs

G

Gable Infill

A gable infill refers to the triangle of cladding used to fill in the gable of a shed, rather than enclosing the full gable end.

G

Growth Rate

Growth rate in a lamb feedlot is the measure of how quickly lambs gain weight and is typically expressed as grams per day.

It is calculated by weighing lambs at the start and end of a feeding period to determine the total weight gained and dividing that by the number of days in the period.

According to the MLA’s Producers’ Guide To Production Feeding For Lamb Growth (PDF Download), for a lamb feedlot to be profitable, lambs generally need to achieve daily growth rates exceeding 300g/day.

A lamb feedlot shed can be used to achieve higher growth rates. For example, lambs under this cover gain an additional 150 grams per day in the winter months.

Growth Rate should be considered alongside the Feed Conversion Efficiency ratio to determine profitability.

I

Induction

Induction is defined by MLA as “the management process when livestock arrive at a feedlot or intensive finishing system that ensures the health and welfare of the new arrivals and the livestock already on feed.”

This process could include ensuring vaccinations are up to date, gradually increasing feed and monitoring shy feeders.

L

Lick Feeders

A lick feeder (such as these Paton and Bromar Engineering examples) controls the amount of feed a lamb can consume at a time by adjusting the flow of feed and restricting access to the sheep’s tongue.

Benefits of this system include less feed wastage and reduced risk of acidosis.

L

Loafing Areas

A loafing area in a lamb feedlot shed is a space away from the main feeding area, and is usually stocked at 1m². External pens are usually stocked between 5 m² and 10m².

This is used to create a low-stress environment, reduce the risk of shy feeders and improve overall animal health.

O

Open Gable Truss

An open gable truss is where one truss is left open/unclad in a gable infill. This helps ensure there is effective airflow through the shed.

O

Orientation

Orientation, in lamb feedlot shed terminology, refers to the direction your shed is positioned.

This determines how exposed the shed is to the prevailing weather and will influence how effective your feedlot shed is in providing weather protection and airflow.

Generally, the recommended orientation for feedlot sheds is the east-west orientation.

However, this will depend on factors like:

- The local climate

- Your feedlot shed design. For example, have you included a side wall?

- Site location, such as how exposed it is.

P

Pop-Top Cover

The Action “pop-top” cover refers to the raised cover over a ridge ventilation gap in a feedlot shed roof.

This helps prevent rain from entering the ridge gap while still allowing hot air to escape through the roof.

P

Price Margin

Price margin usually refers to buy-in prices versus the sale price of lambs.

Put simply, if the cost of production (COP) exceeds the price margin, the system will be unprofitable.

R

Ration Cost

The cost of feed required to finish lambs. This number typically includes feed costs from induction feeding through to finishing.

Feed can be a major cost contributor to a lamb feedlot set-up, so this is an important number to be aware of.

R

Ridge Ventilation

Ridge ventilation refers to the ridge gap or opening at the peak of a lamb feedlot shed.

This gap – usually around 1500mm wide – works with a steep roof pitch to allow heat, moisture, and ammonia to escape.

R

Roof Pitch

Lamb feedlot sheds typically feature a steep roof pitch of between 14 and 18 degrees to help facilitate effective air movement through the shed.

S

Site Slope

Site slope refers to the fall of the site from one end of the shed to the other. A slope between 2-6% is usually recommended for effective water runoff.

S

Summer Pneumonia

Also known as Ovine Respiratory Complex (ORC), Summer Pneumonia often occurs in dusty conditions such as uncovered containment feeding areas.

Lamb feedlot sheds play an important role in preventing summer pneumonia and can dramatically reduce treatment costs.

S

Shy Feeder

A shy feeder is a lamb that avoids feeding in a feedlot, often due to:

- Dietary changes

- Environmental stress

- Social hierarchy

- Underlying illness

It is usually recommended that a shy feeder be removed from the feedlot if it has not adapted after two weeks.

S

Stocking Density

Stocking density or stocking rate refers to the number of sheep in an area (such as a lamb feedlot shed), expressed as a square metre per head.

Industry recommendations for stocking density depend on your feedlot set-up.

For example, a 3-5m² per lamb stocking rate is common for a drought lot or uncovered containment feeding set-up.

However, a stocking rate of around 1m² is common for covered lamb feedlots, including for partial shade setups.

T

Time On Feed

Simply the time lambs spend in the system – an important consideration when feed costs are high. This will depend on details like entry weight, target weight and growth rates.

T

Total Mixed Ration (TMR)

A Total Mixed Ration (TMR) combines feed ingredients such as grains, roughage and supplementary additives into a single mix for consumption.

This approach helps prevent lambs from overfeeding on grain, reducing the risk of acidosis and providing a balanced diet for growth.

That’s a wrap on our guide to lamb feedlot shed terminology! We hope this has been helpful.

If you are looking examples and ideas for your project, check out the gallery below.

Lamb feedlot sheds are set to become important infrastructure for lamb producers looking to stay ahead of the game.

Ready to kickstart your planning?

Have questions about lamb feedlot shed terminology that need answering?

Book a project consultation with the Action team on 1800 687 888 – we would love to hear from you!