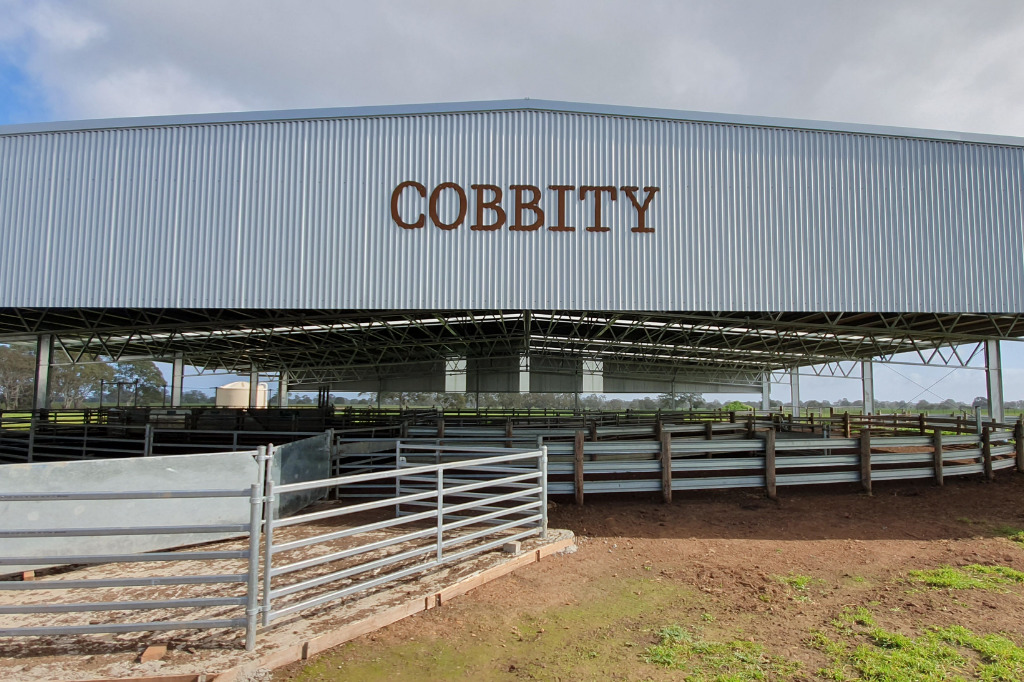

Yard covers are proving to be an invaluable investment for many primary producers, and carefully planning a yard cover before-hand can maximise results and realise the full potential of the investment.

We’ve broken the planning process down into 6 simple steps – and remember that our building consultants are always happy to have a chat.

Effective communication

Yards and yard design

Size and seamless fit

Site location and preparation

Design and customisation

Materials

We go into more detail on each of these points below.

Effective communication

Effective communication is an integral part to any project and is absolutely essential to making smart and effective decisions – a yard cover project is no different.

This starts with us understanding your requirements and your expectations and continues right through the project from sharing plans and designs with the yard supplier and submitting applications to council, to keeping you updated as it progresses.

Yards and yard design

One of the first questions our building consultants will ask is; Is the roof going over existing yards? And, if not: Has the yard design been decided or finalised?

Rest assured the team at Action are able to work with either scenario.

If your roof is going to be covering existing stockyards, one of our consultants will visit the site to measure the fall over the land to determine the necessary column lengths and ascertain the bay spacings required to fit in with the yards.

This ensures that site will not have to be built up and the columns will not interrupt with flow of the sheep through the yards or intrude on working areas.

When it comes to erection, a yard cover can be built over existing yards by either being assembled in the air or built on the ground beside the yards and moved into place by cranes.

On the other hand, if your yard design has not been finalised, the Action team can liaise directly with the yard company (ProWay being our preferred supplier) and share and discuss plans.

By working directly with the stockyard designers, we ensure the least amount of impact on your yarding and the result is a seamless fit over your new yards. We are able to vary bay widths anywhere up to 10 metres, if needed, to avoid clashing with gates or working areas and we can also vary the spacing throughout your yard cover too.

Size and seamless fit

What size will your yard cover need to be, and will it need to fit in with any existing sheds or infrastructure?

If you aren’t 100% sure what size your yard cover needs to be keep in mind factors like the area of yards you want covered and allow for an extra 1-2 metres on each side of the yards – we recommend doing this as it means the yard cover provides complete protection even in the most inclement weather. Other factors like the number of sheep or cattle and workers moving through the yards may also help you determine the best size for your yard cover.

As we have discussed earlier, Action can design and manufacture your yard cover to fit in with existing yards – the same goes for fitting in with existing sheds or other infrastructure.

Site location and preparation

The site is one on the most critical components when putting a roof over your yards.

Once you have decided on the location of the yard cover, the next step is making sure it is prepared properly, keeping in mind that if your yards are already in place you will be limited to the changes you can make.

If you are preparing your site from scratch, the first thing you should do is get in contact with your yard designers to see what is required. The working area of the yards generally would need to be level, and so are the areas where concreting is required. As for the holding yards, these can generally be designed to suit some sort of fall if necessary. One of the most important factors to consider is stormwater, and how to best prepare your site to avoid run-off entering the yards.

If your cover is going over existing yards, we would suggest that you get in contact with one of our building consultants and arrange an on-site meeting with them.

Our building consultants are regularly visiting sites to measure the fall over the land (to determine the necessary column lengths) and ascertain the best bay spacings required to fit in with the yards.

Design and customisation

While this is often the most exciting step it can also prove to be challenging – but it doesn’t need to be.

- Gable infills provide another layer or angle of protection while still allowing adequate airflow throughout the cover.

Partly clad walls play a similar role to gable infills. Partly cladding some or all of the walls on your yard cover ensures both workers and livestock are shielded from the prevailing weather whilst still providing sufficient ventilation.

- Gutters. When planning the guttering system for your yard cover, factor in what you intend to do with the stormwater collected, the most convenient location for a rainwater tank and the average rainfall in your area.

Slotted fascia gutters or an Action custom gutter are the most common guttering systems for yard covers. We discuss these in more detail in our Ultimate Guide to Gutters.

- Sky lighting and artificial lighting such as hi-bays can be very beneficial, particularly over working area.

With skylights, workers can take full advantage of the natural light during the day for yard work while still being kept out of the weather.

We use a quality skylight product that does not go brittle and is opaque meaning it does not cast shadows on the ground below.

For more information about the pros and cons of using skylights read our article; Installing skylights in your shed

Materials

Lastly, but certainly not least is the material selection.

On our yard covers both the columns and trusses are fully hot dip galvanised to provide the ultimate level of protection against rust and corrosion – this is standard on any of our sheds.

When it comes to cladding however, there are more options. Click the links below to learn more about your options