If you are looking to invest in a new shed it is a good idea to make sure the shed doesn’t have painted columns. This is because a shed with painted columns is an inferior product compared to a shed with hot-dip galvanised columns.

Why should you avoid buying a shed with painted columns?

Here’s why.

Painted Coating

A zinc-rich paint coating, often referred to as cold galvanising:

- is soft,

- varies in thickness,

- is not abrasion resistant,

- has a short lifetime,

- and provides limited cathodic protection (if any).

Painted Coating versus Hot-Dip Galvanized Coating

These resources from the American Galvanizers Association help explain the advantages and disadvantages of zinc rich paint coatings and hot-dip galvanizing.

Hot-Dip Galvanised Steel vs Zinc Rich Paint

Hot-Dip Galvanised Steel vs Paint

Some important points from these resources include:

- Hot dip galvanising (HDG) “has three times the abrasion resistance” than that of Zinc rich paint (ZRP).

- “Paint coating thickness on all surfaces is a variable and uniform as the applicator, with corners and edges highly susceptible to corrosion because of thin films.”

- “The HDG coating generally exceeds the minimum coating thickness requirement of ASTM standards; based largely on the chemistry of the substrate steel and surface condition of the steel prior to cleaning.”

- “Sun, heat, wind and weathering are constants that result in paint typically requiring touch-up and replacement in 12-15 years, costing far more than galvanizing over the intended life of the project.” In our experiences with zinc-paint this touch-up and replacement timeframe has been much shorter than the suggested 12-15 years.

- “HDG typically has no maintenance costs and so the initial cost is the total life-cycle cost.”

Hot Dip Galvanized Coating

As we discuss in this article, hot-dip galvanized steel:

- has a coating that is made up of four layers – three of which are harder than the base steel itself.

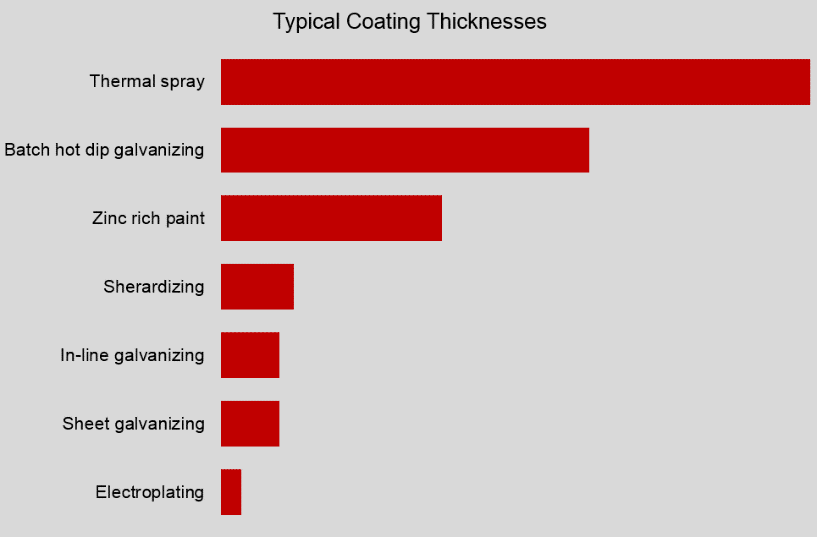

- is significantly thicker than paint (see below) and provides a complete, uniform coverage.

- is abrasion resistant due to the three zinc-alloy layers that form.

- Provides barrier, patina and cathodic protection. The advantage of cathodic protection is that it is sacrificial so that if small areas of steel are exposed by impact or abrasion they will still be protected. As a result, the hot-dip galvanized steel does not need small damaged areas to be touched up or repaired – unlike paint – saving you both time and money.

- will not require maintenance for over 100 years making it the most cost-effective coating over the long-term.

Read our guide to hot-dip galvanising or watch the video below to learn more about the process and the protection it provides your shed.

We hope this article helps you understand the difference between paint coatings and hot-dip galvanizing. If you have any questions about hot-dip galvanized farm sheds call us on 1800 68 78 88.

You might also like our Learning Hub which has other useful articles, videos and brochures.