The Jakabul shearing shed complex was an exciting project to be a part of. An impressive 9-stand set-up, it champions safe and efficient working conditions.

The movement towards safe and efficient shearing sheds has been at the forefront of the industry in recent years as woolgrowers look to overcome worker shortages by upgrading facilities to improve staff retention and attraction.

Aided by industry developments and resources such as the AWI board design and Safe Sheds program, shearing shed upgrades and new builds have been popular even with subdued wool prices.

One of the most recent projects Action Steel has been involved in is the impressive 9-stand Jakabul shearing shed complex.

Whether you are also planning a state-of-the-art facility or simply looking at ways to make your existing shed safer and more efficient, the Jakabul shearing shed is sure to be an inspiration!

Project Summary

Size: 80m (L) x 30m (W) x 5.2m (H)

Configuration: Single gable shed with covered yards and a 9-stand U-shape flat board.

Fit Out Supplier: ProWay Livestock Equipment

Location: Apsley VIC

Download the West Wimmera brochure to view more Action shed builds in the area.

Build Date: 2023

Keep reading to learn more about this project – another successful collaboration between Action Steel and ProWay Livestock – in detail.

Project Details

Here are some of the key details and features of this project that make it such a showcase project, from the single gable configuration to the seamless fit of the yards and fit-out.

Site Preparation

A well-planned and prepared site is recommended for any shed project – you can learn about this here – and this was the case for the greenfield site at Jakabul. This made installation straightforward and keeps the shed and covered yards accessible even in wet weather.

Access

Carefully planned access points ensure the sheep flow easily into the shed, helping to provide a low-stress environment for both the sheep and the shearers.

Ventilation

Similarly, ventilation is one of the most important considerations for providing comfortable working conditions. This is achieved in the Jakabul shearing shed with a combination of ridge vent in the roof through the shed and wall vents.

Sliding doors can also be opened as needed to provide additional natural airflow.

In the covered yards, gable infills have been installed to help find the ideal balance of airflow and protection from the prevailing weather.

Lighting

To provide well-lit working areas including over the board and in the wool handling areas, hi-bay lights suspended from the trusses have been used throughout the shed. These have also been included in the under cover yard area which makes yard work hours more flexible.

Configuration

The configuration of the shed is a smart choice. A single gable configuration is cost-effective and incorporating covered yards is too. Covered yards typically cost less than having additional grating area and covered yards are also more versatile. They can be put to good use throughout the year for yard work – rain, hail or shine!

Board Design

Arguably one of the most important and debated features of a shearing shed is the board and board design. In this case, the board is a 9-stand flat board in a U-shape configuration.

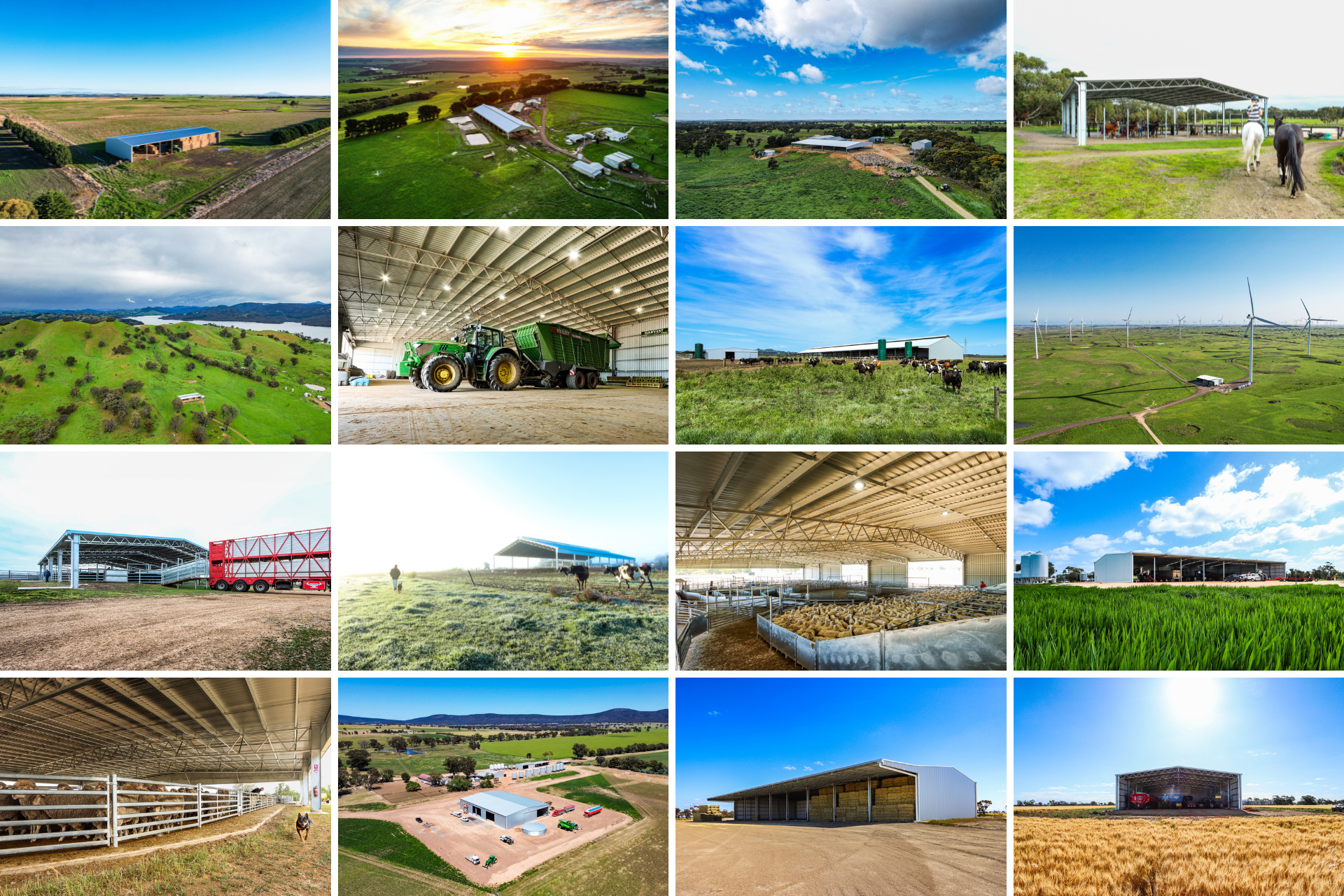

Jakabul Shearing Shed Project Gallery

Browse the gallery to view the project in action at the first shear!

Project Price Guide

In 2024 a similar project would cost approx. $450,0000 – $550,000 including GST, footings and installation.

Please note that this price guide does not include the fit-out component.

Relevant Resources

Here is a selection of articles and resources that might also be relevant to your project planning.

- How Much Does It Cost To Build A Shearing Shed?

- Raise Board Shearing Sheds: Pros, Cons & Prices

- The Best Shearing Shed Fit-Out Suppliers

- Latest Projects Gallery

We hope you have found this project article of interest! If you are planning a shearing shed build, our building consultants are available to provide ideas and advice. Call us on 1800 687 888 – we would love to partner with you on your project.